-

Products related to categories: servo, frequency conversion, HMI, driver, distributed DCS, IPC (PC bus industrial computer), PLC (programmable control system), DCS (distributed control system), FCS (field bus system), robot and other products and technical services.

-

Applications: Wind energy, automobile, ship, transportation, manufacturing, aviation, petroleum, natural gas, thermal power, thermal power, nuclear energy, steel, metallurgy, mining, power and other industries

-

Controller PLC\Robot servo drive Electro-hydraulic servo valve\DCS system/Distributed control systemSystem rack\Communication adapter\Analog output\Analog input\

-

\Multi-meter energy meter\Ignition\circuit board\Crimp terminal\Electric ac drive\Low voltage DC power module\Electro-hydraulic\servo valve\Automatic control system\exchange\Network communication module

controller\Processor module\dynamo\Electric machine\Servo drive\Touch screen\Input/output module\Water treatment monitoring system\Automobile\manufacturing system\Thermoelectric control system\ -

Digital output\Digital input\Mechanical protection system\High speed CPU

-

Electric power system\Chemical testing system\Petroleum control system\Tension monitoring system

-

DCS Distributed\control system\Steel control system\Steam\turbine system\Power generation system\

-

Thermal power generation system\Wind power system\Medium and high voltage frequency\conversion system\Precision motion system\Programmable control system\

-

Singapore New Energy Corporation

-

Geylang Bahru Industrial Estate

-

การทางหลวงแห่งประเทศไทย

-

American Petroleum Group

-

Indian shipping works

-

Pakistan Gas Company

-

Russian Automotive Industry Corporation

-

Brazilian Mining Company

-

Bangladesh Hydro power Plant

-

Egyptian Iron and Steel Manufacturing Co

-

Groupe d’exploitation du métro français

-

Für meinen vater

-

Mongolia Wind Farm

-

Empresa venezolana de procesamiento de petróleo

-

alibaba

-

Sichuan Huayingshan Power Plant

-

Huadian Datong Power Plant

-

Guodian Shuangyashan Power Generation Co., Ltd.

-

Baosteel Group Xinjiang Bayi Steel Co., Ltd.

-

Guodian Changzhou Power Plant

-

Xingtai Iron and Steel Co., Ltd.

-

Guodian Fee County Power Generation Co., Ltd.

-

Yangzhou Second Power Plant

-

Sichuan Jintang Power Plant

-

Xingcheng Special Steel Co., Ltd.

-

Quzhou Yuanli Metal Products Co., Ltd.

-

Zijin Mining Group

-

(Bangladesh) Metro Construction Company

-

WuHan steel co., ltd.

-

MaAnShan steel co., ltd.

ABB NGC8206 Natural Gas Chromatograph Dual Unit

ABB NGC8206 Natural Gas Chromatograph Dual Unit

The ABB Natural Gas Chromatograph (NGC) and Process Gas Chromatograph (PGC) continually analyze natural gas or process gas streams on-site, determine composition and calorific value, and store the analysis information.

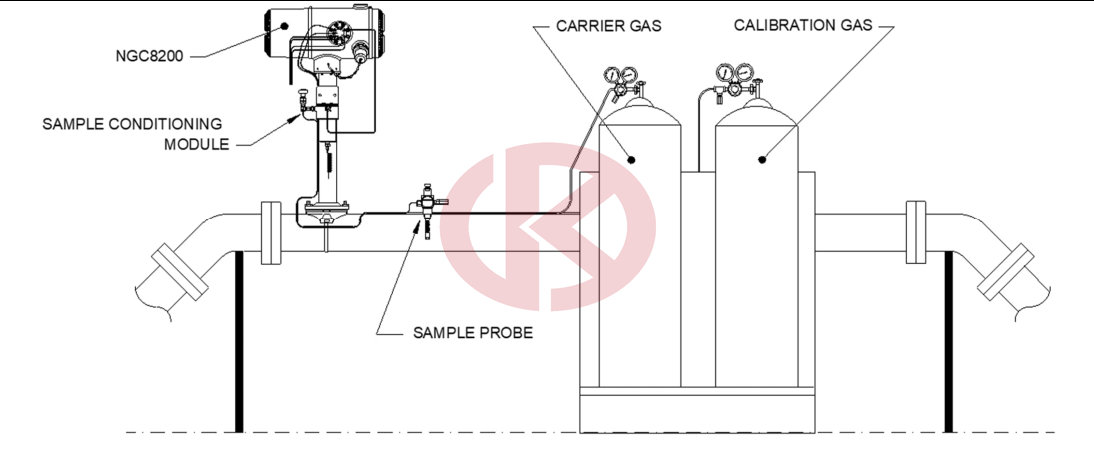

System components This compact device requires minimal installation time and is configured and calibrated at the factory. A typical installation has the following components: Analyzer: a single analyzer supports a single or multiple streams (up to 4) Sample probe: captures the gas sample from the pipeline Sample conditioning module(s): prepares the sample before it enters the analyzer Carrier gas: assists the flow of the gas sample Calibration gas: gas blend with detectable components to determine baseline analysis Tubing: gas lines to deliver and vent gas to and from the analyzer. Figure 1-1 shows the analyzer in a typical single stream pipeline installation. This scenario includes a sample probe, an optional sample conditioning module, and carrier and calibration gas. Lines for the entry of the gas sample, carrier gas, and calibration gas are installed into the analyzer’s feedthrough inlets. The sample probe captures the gas sample which is fed to the sample conditioning module for processing before it enters the analyzer. Carrier gas assists the gas sample flow through the device. Figure 1-1: Typical single stream installation

The NGC8206 analyzes each sample utilizing established chromatographic techniques. The resulting information consists of mole percent values for the following: • “Air” (Contains N₂, Ar, CO and O₂ but not CO₂) • C₁, CO₂, C₂, C₃, iC₄, nC₄ • NeOC5, iC₅, nC₅, C₆+

Using process chromatographic techniques, the columns are back flushed so that the NGC8206 measures a C₆+ peak. Users may input the results of a comprehensive lab analysis that reflects the split or ratio of C₆ through C₁₀ components. This ratio can be used in subsequent analysis and energy calculations. Calculated values include:

• Gas compressibility per AGA 8

• Real Relative Density (Specific Gravity)

• Btu/CV Value

• GPM (gallons of liquid per thousand cubic feet)

• Wobbe Index

• Methane Number

• Optional calculations can include: AGA 10 speed of sound, Hydrocarbon Dew Point

Installation

The NGC8206 is a weatherproof device designed for installation “on the pipe” near to the sampling point. This means it is acceptable to mount outside - in a temperature range of 0°F to 130°F (–18°C to 55°C) [provides reliable operation for –20°F to 130°F (–29°C to 55°C) with low temperature option] onto a pipeline with 2" to 12" pipe sizes or with an optional pole mount configuration. A cold weather enclosure is also available if ambient conditions are below either the sampled gas dew point or the operational specifications of the unit.

Sample conditioning system

The integral stream selector for the NGC8206 allows sampling up to four (4) different natural gas streams. Up to two of these sample streams can be designated as the “calibration/ validation sample”. Optional sample conditioning modules are available to address natural gas streams that need additional filtering and “speed loops” to reduce sample transport lag times.

The NGC8206 is designed to retain historical data. This data can be used for custody transfer needs, verify transmitter operation over time, and provide a limited data backup for communication link reliability. The user is allowed to configure the period of the data retained by the NGC8206 via the Operator Interface. The default¹ memory configuration provides the most recent 480 analysis cycles containing: • Normalized components • Un-normalized components • Ideal Btu/CV • Real Btu (wet and dry) / CV (superior and inferior) • Relative density (specific gravity)

• Density • GPM • Wobbe index • Alarms

The NGC8206 is designed to retain historical data. This data can be used for custody transfer needs, verify transmitter operation over time, and provide a limited data backup for communication link reliability. The user is allowed to configure the period of the data retained by the NGC8206 via the Operator Interface. The default¹ memory configuration provides the most recent 480 analysis cycles containing: • Normalized components • Un-normalized components • Ideal Btu/CV • Real Btu (wet and dry) / CV (superior and inferior) • Relative density (specific gravity)

- AEROTECH

- MOOG

- ABB

- HIMA

- GE

- Prosoft

- EMESRON

- EPRO

- rockwell

- Technical Data

- Product Information

- Industry Information

- Company News

- DEIF

- Triconex

- UNIOP

- REXROTH

- Woodward

- Lumentum

- Honeywell

- National Instruments

- Bently Nevada

- MOTOROLA

- FOXBORO

- Enterasys

- KOLLMORGEN

- SIEMENS

- SST

- YOKOGAWA

- sieger

- RELIANCE

- meggitt

- VMIC

- ALSTOM

- EATON

- METSO

- Abaco

- HIRSCHMANN

- Rolls-Royce

- BENDER

- AMAT

- Brand

- ORMEC

- WATLOW

- Schneider

- PRAXIS-Automation

- BASLER

- Kongsberg

-

GE Industrial System Mark V Display MMI 323A2374P2

-

VMEBUS RACK VME32 BACKPLANE 100-240V/50-60 Hz/1200W

-

IBA ibaLink-SM-128V-i-2oVMEbus Interface Board SM128V

-

VMIC VME-PMC-CADDY VME-Carrier Board for 2 PMC Modules

-

ABB REF620E_1G Feeder Protection and Control

-

ABB SACO16D1 Digital Annunciator Unit

-

ABB REF620 HBFNACNNNEA1BNN11G Feeder Protection and Control

-

GE UT150-2 CPU MODULE CARD FOR CE2000 CONTROLLER

-

ALSTOM TANSFORMER MAINTENANCE KIT 1000KVA UTHC GEC

-

ABB DASD146 3ASC25H270 Lifter controller accessories DASD145

-

ABB DASD147 3ASC25H280 Lifter controller accessories DASD107

-

ABB SCC-K Converter NO2/NO converter and Thermal converter 3KXG801000U0100

-

Siemens 6AV6643-0CD01-1AX1 SIMATIC MP 277 10" Touch

-

ABB UAC095AE01 HIEE300788R0001 Communication Control IO Board

-

ABB AC800PEC Measuring Interface PECMIUAD140 PECMI UA D140

-

ABB 500PSM03 1MRB150038 Power Supply module

-

Valmet metso D201563L Control unit accessories

-

Valmet metso D201473L AII8 Control unit accessories

-

EATON XVS-430-10MPI-1-10 Touch panel 24 V DC TFTcolor, ethernet, RS232

-

bently 60M100-00 Condition Monitoring System

-

ABB 3BHB004791R0101 IGCT Gate Power Supply Unit

-

ABB TAS.580.0550.G00 HARDWARE BOARD ABB100 COMPONENTS SIDE

-

ABB SYN5201A-Z,V277 3BHB006714R0277 Automatic single-channel synchronization unit

-

ABB SUE3000 1VCF750090R0804 Operation screen unit 1VCR007346

-

ABB SENSYCAL FCU400-IR Product Summary

-

ABB SDCS-CON-2-COAAT 3ADT220090R2 DCS Thyristor Power Converters accessories

-

ABB SCYC51220 63901075c Control Module

-

Siemens SYNCHRONOUS SERVOMOTOR 1FK6084-6AZ21-9ZZ9-Z S05

-

Siemens SYNCHRONOUS SERVOMOTOR 1FK6063-6AF71-1EH0

-

FOXBORO FBM241/b/c/d Discrete I/O Interface Modules

-

FOXBORO FBM242, Externally Sourced, Discrete Output Interface Module

-

FOXBORO FBM244, 0 to 20 mA I/O Interface Module with HART Support

-

FOXBORO FBM245, 0 to 20 mA I/O Interface Module with HART Support

-

FOXBORO FBM247, Current/Voltage Analog/Digital/Pulse I/O Configurable Interface Module

-

FOXBORO FBM218 HART Communication Redundant Output Interface Module

-

FOXBORO FBM219 Discrete I/O Interface Module

-

FOXBORO FBM222, Redundant PROFIBUS Communication Interface Module

-

FOXBORO FBM227, 0 to 10 V dc, Contact/dc I/O Interface Module

-

FOXBORO FBM228 FOUNDATION fieldbus Interface Module

-

FOXBORO FBM229 DeviceNet Communication Interface Module

-

FOXBORO FBM230 Field Device System Integrator Module

-

FOXBORO FBM231 Field Device System Integrator Module

-

FOXBORO FBM237, 0 to 20 mA Output Interface Module

-

FOXBORO FBM238, Digital 24DI/8DO Mixed Interface Module

-

FOXBORO FBM239, Discrete 16DI/16DO Interface Module

-

FOXBORO FBM240, Redundant with Readback, Discrete Output Interface Module

-

foxboro FBM208 Redundant with Readback, 0 to 20 mA I/O Interface Module

-

FOXBORO FBM214b HART Communication Input Interface Module

-

FBM215 HART Communication Output Interface Module

-

FBM216b HART Communication Redundant Input Interface Module

-

FOXBORO FBMSVH valve power amplifier card

-

foxboro FBM201/b/c/d Analog Input 0 to 20 mA, 0 to 100 mV, 0 to 5 V, 0 to 10

-

FOXBORO FBM202 Thermocouple/mV Input Interface Module

-

FOXBORO FBM204 0 to 20 mA I/O Interface Module

-

foxboro FBM206 Pulse Input Interface Module

-

FBM207/b/c Voltage Monitor/Contact Sense Input Interface Modules FBM208

-

0 to 20 mA I/O Interface Module FBM211 FOXBORO

-

FOXBORO P0916FJ 3M Communication cable

-

ALSTOM ALSPA CE80-20 Bus Interface unit

-

Display Controller Rolls-Royce MPCF1-10.4

-

ROCKWELL 2094-BC07-M05-S Kinetix 6000 Integrated Axis Module

-

GE IGBT ProX690-1E1-0W0H0 Phase-controlled control module of gas compression unit

-

ALSTOM MVTU11K1CD0751G Control relay

-

ALSTOM MVTU12K1CD0751G Control relay

-

triconex 3382 Pulse Input Module, Enhanced

-

triconex 3451 Solid-State Relay Output Module

-

triconex Digital Output Module, Supervised 3411

-

triconex Digital Output Module 3401

-

triconex Digital Input Module, High Resolution 3311

-

triconex Digital Input Module 3301

-

triconex 3482 High-Current Analog Output Module

-

triconex Model 3481 Analog Output Module

-

Triconex 9793-610F Analog Input/Digital Input Termination Panels Kit, Hazardous Location

-

Triconex 9573-610F Digital Input Termination Panel Kit, Hazardous Location

-

Triconex 2483 Analog Output Baseplate Kit, HART 2483A

-

Triconex 2481 Analog Output Baseplate Kit

-

Triconex 2480A-F Analog Output Baseplate Kit, Hazardous Location

-

Triconex 2451 Solid-State Relay Output Baseplate Kit

-

Triconex 2402-F Digital Output Baseplate Kit, High Voltage 2402A-F

-

Triconex 2401 Digital Output Baseplate Kit 2401H 2401L

-

Triconex 2381 Pulse Input Baseplate Kit 2381A

-

Triconex 2361 Analog Input/Digital Input Baseplate Kit

-

Triconex 2354 Analog Input Baseplate Kit, HART 2354A

-

Triconex 2352A-F Analog Input Baseplate Kit, Hazardous Location

-

Triconex 2352 Analog Input Baseplate Kit for TC, RTD, and 4-20mA (requires 2 of part number 9764-510F)

-

Triconex 2351 Analog Input Baseplate Kit

-

Triconex 2342 Analog Input/Digital Input Baseplate Kit External Termination 2342A-F

-

Triconex 2302-F Digital Input Baseplate Kit, High Voltage 2302A-F

-

Triconex 2301 Digital Input Baseplate Kit

-

Triconex 2292 I/O Bus Termination Kit, MP Baseplate

-

Triconex 2291 I/O Bus Termination Kit, I/O Baseplate

-

Triconex 2281 I/O Bus Extender Module Kit

-

Triconex 2211 Communications Integration Module Baseplate Kit

-

Triconex 2201 Communications Module Baseplate Kit

-

Triconex 2101 Main Processor Baseplate Kit

-

Triconex 5483 Analog Output TriPak, HART 5483A

-

Triconex 5382A Pulse Input TriPak, Enhanced, Hazardous Location

-

Triconex 5382-1 Pulse Input TriPak, Enhanced

-

Triconex 5451 Solid-State Relay Output TriPak

-

Triconex 5402-F Digital Output TriPak, High Voltage

-

Triconex 5411H Digital Output TriPak, Supervised, High Current

-

Triconex Digital Output TriPak, Low Current 5401L

-

Triconex Digital Output TriPak 5401

-

Triconex Digital Input TriPak, High Voltage 5302-F

-

Triconex Digital Input TriPak, High Resolution, High Voltage 5312-F

-

Triconex Digital Input TriPak, High Resolution 5311

-

Triconex Digital Input TriPak 5301

-

SAR 12 029.379519 GE Ring antenna CV(Restricted products)

-

Triconex Analog Output Tripak High-Current 5482-1

-

Triconex Analog Output TriPak 5481-1

-

Triconex Analog Input TriPak HART Hazardous Location 5354A 5354AS2

-

Triconex Analog Input TriPak HART 5354 5354S2

-

Triconex Analog Input Tripak RTD/TC/4-20 mA 5352 5352S2

-

Triconex Analog Input/Digital Input TriPak 5361 5361S2

-

Triconex Analog Input TriPak 5351 5351S2

-

Triconex Communication Module TriPak 5201 5201S2

-

Triconex Communications Integration Module TriPak 5211 5211S2

-

triconex Main Processor TriPak 5101 5101S2

-

TRICONEX 2211 Discrete input/output module

-

CIM3211 Triconex Tricon Communication Model

-

triconex Communication Module cm3201

-

MICRO INNOVATIONDISPLAY INTERFACE PANLE MC2-442-57CQB-1-2G

-

ABB NextMove ESB-2 motion controller

-

IS200SSCHAH2A GE COMMUNICATION TERMINATION TERMIINAL

-

GE IS200WREAH1A PROTE INTERFACE BOARD, EMERG

-

GE IS420UCSCH1B Processing Module UCSC QUAD CORE 1.2GHZ 4GB CONTROLLER

-

UniOP eTOP33C HMI touch unit Product Overview

-

ABB DRIVEMONITOR VERSION 4000 DRIVE RBOX316-ABB-00

All new products and surplus products of the industrial intelligence industry, as well as the discontinued products of the original manufacturers. We are not an authorized distributor or representative of any of the above manufacturers (except for brand authorization). The trademarks, brand names and brands appearing in this agreement are the property of their respective manufacturers.

COPYRIGHT© 2003-2026 Copyrighted

Phone(WeChat/Whatsapp)

+086-181 4410 0983

No 1134 Jimei North Road,

Hong Kong Office:

Guan Tang District, Hong Kong,