-

Products related to categories: servo, frequency conversion, HMI, driver, distributed DCS, IPC (PC bus industrial computer), PLC (programmable control system), DCS (distributed control system), FCS (field bus system), robot and other products and technical services.

-

Applications: Wind energy, automobile, ship, transportation, manufacturing, aviation, petroleum, natural gas, thermal power, thermal power, nuclear energy, steel, metallurgy, mining, power and other industries

-

Controller PLC\Robot servo drive Electro-hydraulic servo valve\DCS system/Distributed control systemSystem rack\Communication adapter\Analog output\Analog input\

-

\Multi-meter energy meter\Ignition\circuit board\Crimp terminal\Electric ac drive\Low voltage DC power module\Electro-hydraulic\servo valve\Automatic control system\exchange\Network communication module

controller\Processor module\dynamo\Electric machine\Servo drive\Touch screen\Input/output module\Water treatment monitoring system\Automobile\manufacturing system\Thermoelectric control system\ -

Digital output\Digital input\Mechanical protection system\High speed CPU

-

Electric power system\Chemical testing system\Petroleum control system\Tension monitoring system

-

DCS Distributed\control system\Steel control system\Steam\turbine system\Power generation system\

-

Thermal power generation system\Wind power system\Medium and high voltage frequency\conversion system\Precision motion system\Programmable control system\

-

Singapore New Energy Corporation

-

Geylang Bahru Industrial Estate

-

การทางหลวงแห่งประเทศไทย

-

American Petroleum Group

-

Indian shipping works

-

Pakistan Gas Company

-

Russian Automotive Industry Corporation

-

Brazilian Mining Company

-

Bangladesh Hydro power Plant

-

Egyptian Iron and Steel Manufacturing Co

-

Groupe d’exploitation du métro français

-

Für meinen vater

-

Mongolia Wind Farm

-

Empresa venezolana de procesamiento de petróleo

-

alibaba

-

Sichuan Huayingshan Power Plant

-

Huadian Datong Power Plant

-

Guodian Shuangyashan Power Generation Co., Ltd.

-

Baosteel Group Xinjiang Bayi Steel Co., Ltd.

-

Guodian Changzhou Power Plant

-

Xingtai Iron and Steel Co., Ltd.

-

Guodian Fee County Power Generation Co., Ltd.

-

Yangzhou Second Power Plant

-

Sichuan Jintang Power Plant

-

Xingcheng Special Steel Co., Ltd.

-

Quzhou Yuanli Metal Products Co., Ltd.

-

Zijin Mining Group

-

(Bangladesh) Metro Construction Company

-

WuHan steel co., ltd.

-

MaAnShan steel co., ltd.

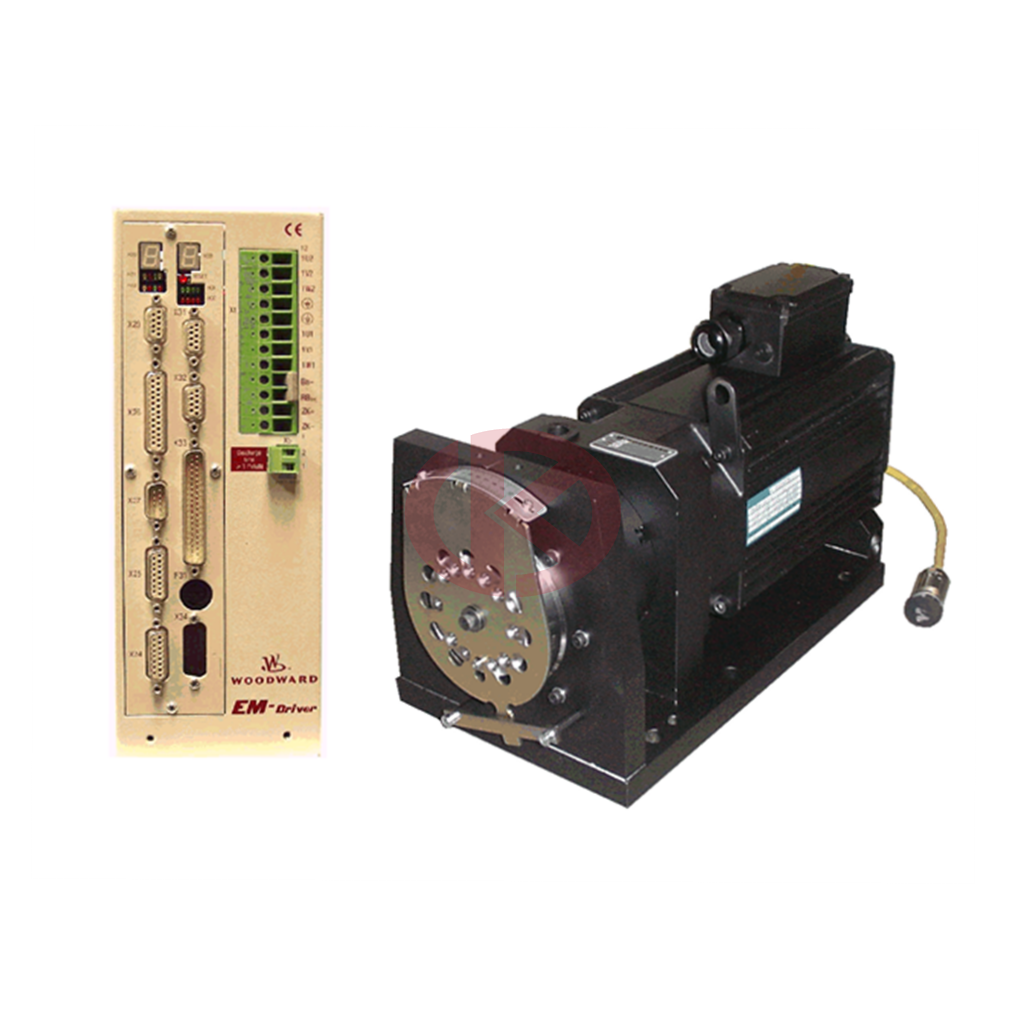

Woodward EM-80/EM-300 Actuator system

Woodward EM-80/EM-300 Actuator system

The EM-80 and EM-300 are all-electric actuator systems that provide a nominal

40° of actuator output rotation. Each system consists of a three-phase brushless

ac motor which drives a high-precision planetary reduction gear box. A dedicated

driver controls the actuator position.

A complete system consists of:

an actuator (Woodward-supplied) (Chapter 4)

a driver (Woodward-supplied) (Chapter 5)

a resolver cable (Woodward-supplied)

shielded power cable

shielded motor drive cable

an EMI filter (Woodward-supplied) (Chapter 6)

metal cabinet enclosure

15- and 25-pin filter pin D-sub connector adapters (Woodward-supplied)

protected 24 Vdc power source

The actuator is available in two versions, offering two work output levels, EM-80

and EM-300 (see the specifications in Chapter 9). Both versions use the same

three-phase brushless AC motor.

The difference in output is achieved by the use of two different gearboxes. The

EM-80 uses a single-stage planetary 1:7 gear ratio, while the EM-300 uses a

two-stage planetary 1:20 gear ratio.

The motor–gearbox combination comes assembled on a mounting bracket with a

fixed hole pattern. Although the EM-300 is longer than the EM-80, both use the

same mounting hole pattern, allowing the actuators to be interchangeable.

The output flange provides an easy mounting surface for a variety of lever

configurations, and is equipped with a rugged pointer and scale for quick output

position reference while working on the prime mover. A breakaway extension and

two stop pins form a simple means of detecting whether the actuator has been

driven outside its operating boundaries.

Electrical connections are made in a standard, shielded, three-phase terminal

box mounted on the motor, and will accommodate standard cable. The resolver

cable has a 1 m (39”) flying lead that removes the connector from the high

vibration environment of the prime mover. The use of the specified resolver cable

and connector will help ensure correct connections to the driver.

The EM-80 and EM-300 actuators have different position-sensing systems. Both

systems use the same hollow shaft resolver, producing a sine and cosine wave

output with an overall accuracy of 12 arc-minutes. This resolver is mounted at the

rear of the motor and looks at the relative position of the motor shaft.

The EM-80 uses only the resolver since the 1:7 gear ratio within the gearbox

allows full stroke of the actuator output flange with less than one full revolution of

the motor shaft.

The EM-300 has a 1:20 gearbox ratio to achieve the required torque output.

Because of this, the motor shaft rotates more than one full revolution to achieve

full stroke. To ensure proper position indication over the full range, a 10-turn

potentiometer is added behind the resolver to supply a coarse position signal

from which the correct rotor revolution is deduced. The same resolver as used on

the EM-80 gives the accurate position within that revolution.

Motor Controller Module Description

The motor controller module is a digital closed loop motor control, which works

with a position loop at 62.5 μs. For position feedback, it receives a resolver signal

form the motor shaft. The motor controller configuration is divided into several

functional modules. The main modules are the:

Positioning/encoder module

Position control module

Speed control module

Torque/current control module

PLC logic module

The positioning/encoder module manages the resolver feedback signal and the

“engine” controller position command signal. The module receives both setpoint

and actual and generates an output to the position control module. The position

control module generates an output to the speed controller module. It signals the

speed control module which direction to rotate and how fast. These three

modules determine the dynamic behavior of the actuator system.

The speed control module generates an output to the torque/current control

module. The torque/current control module controls the excitation of the proper

motor phase with the proper current level. The current is limited to limit the

torque.

The PLC logic module is programmed to convert the “engine” controller position

command signal into a hexadecimal position address. The PLC is programmed

with the specific algorithms to define rotation direction and stroke. The PLC and

the motor controller module are communicating by means of a parallel interface.

The interface takes care of the cyclic update of the position command signals

and the non-cyclic calls for parameters.

The PLC logic program also defines the start-up sequence and enabling of the

motor control module.

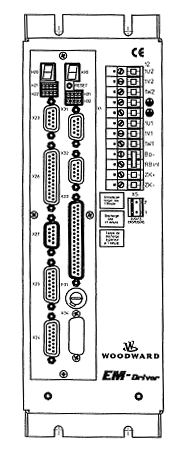

Motor Driver Module Description

The Motor Driver module consists of two parts, the feed current converter on the

mains side and the motor-end inverter.

The supply converter for generating the intermediate circuit voltage is

designed as an unregulated diode bridge. To reduce the starting current

inrush, the system charges the intermediate circuit capacitors via a charging

resistor (an NTC thermistor).

The IGBT motor-end inverter processes the transistor control signals, which

the controller supplies, and provides the measuring signals for closed-loop

control. The Motor Driver module has its own monitoring facilities (selfprotecting

power section).

Feed Current Converter

Within the Motor Driver module, the feed current converter is an unregulated

rectifier with starting current load relief.

The driver is the device which receives the actuator position command signal

from the controller and positions the actuator by means of controlling the current

and potential of the three phases of the actuator electromotor. The driver is

loaded with configuration settings for the EM-80 or EM-300 actuator and with an

application file for the proper and safe operation of the actuator system.

The driver is an integrated package of two main modules.

Motor Controller module

Motor Driver module

3522-1009

Marine Type Approval Compliance

Bureau Veritas (BV) Certified under BV Rules for the Classification of Steel

Ships.

EM 80 Driver 3522-xxxx

EM300 Driver 3522-xxxx

EM80 Actuator 8256-308

EM300 Actuator 8256-310

Det Norske Veritas Drivers 3522-1004 through 3522-1012

(DNV) EM-300 Actuators 8256-308 & 8256-310

Certified for Marine Applications

Temperature: Actuator Class B, Driver Class A

Humidty: Actuator and Driver Class B

Vibration: Actuator Class B, Driver Class A

EMC: Actuator and Driver Class A

Enclosure: Actuator Class C, Driver Class A

- AEROTECH

- MOOG

- ABB

- HIMA

- GE

- Prosoft

- EMESRON

- EPRO

- rockwell

- Technical Data

- Product Information

- Industry Information

- Company News

- DEIF

- Triconex

- UNIOP

- REXROTH

- Woodward

- Lumentum

- Honeywell

- National Instruments

- Bently Nevada

- MOTOROLA

- FOXBORO

- Enterasys

- KOLLMORGEN

- SIEMENS

- SST

- YOKOGAWA

- sieger

- RELIANCE

- meggitt

- VMIC

- ALSTOM

- EATON

- METSO

- Abaco

- HIRSCHMANN

- Rolls-Royce

- BENDER

- AMAT

- Brand

- ORMEC

- WATLOW

- Schneider

- PRAXIS-Automation

- BASLER

- Kongsberg

-

FOXBORO FBM241/b/c/d Discrete I/O Interface Modules

-

FOXBORO FBM242, Externally Sourced, Discrete Output Interface Module

-

FOXBORO FBM244, 0 to 20 mA I/O Interface Module with HART Support

-

FOXBORO FBM245, 0 to 20 mA I/O Interface Module with HART Support

-

FOXBORO FBM247, Current/Voltage Analog/Digital/Pulse I/O Configurable Interface Module

-

FOXBORO FBM218 HART Communication Redundant Output Interface Module

-

FOXBORO FBM219 Discrete I/O Interface Module

-

FOXBORO FBM222, Redundant PROFIBUS Communication Interface Module

-

FOXBORO FBM227, 0 to 10 V dc, Contact/dc I/O Interface Module

-

FOXBORO FBM228 FOUNDATION fieldbus Interface Module

-

FOXBORO FBM229 DeviceNet Communication Interface Module

-

FOXBORO FBM230 Field Device System Integrator Module

-

FOXBORO FBM231 Field Device System Integrator Module

-

FOXBORO FBM237, 0 to 20 mA Output Interface Module

-

FOXBORO FBM238, Digital 24DI/8DO Mixed Interface Module

-

FOXBORO FBM239, Discrete 16DI/16DO Interface Module

-

FOXBORO FBM240, Redundant with Readback, Discrete Output Interface Module

-

foxboro FBM208 Redundant with Readback, 0 to 20 mA I/O Interface Module

-

FOXBORO FBM214b HART Communication Input Interface Module

-

FBM215 HART Communication Output Interface Module

-

FBM216b HART Communication Redundant Input Interface Module

-

FOXBORO FBMSVH valve power amplifier card

-

foxboro FBM201/b/c/d Analog Input 0 to 20 mA, 0 to 100 mV, 0 to 5 V, 0 to 10

-

FOXBORO FBM202 Thermocouple/mV Input Interface Module

-

FOXBORO FBM204 0 to 20 mA I/O Interface Module

-

foxboro FBM206 Pulse Input Interface Module

-

FBM207/b/c Voltage Monitor/Contact Sense Input Interface Modules FBM208

-

0 to 20 mA I/O Interface Module FBM211 FOXBORO

-

FOXBORO P0916FJ 3M Communication cable

-

ALSTOM ALSPA CE80-20 Bus Interface unit

-

Display Controller Rolls-Royce MPCF1-10.4

-

ROCKWELL 2094-BC07-M05-S Kinetix 6000 Integrated Axis Module

-

GE IGBT ProX690-1E1-0W0H0 Phase-controlled control module of gas compression unit

-

ALSTOM MVTU11K1CD0751G Control relay

-

ALSTOM MVTU12K1CD0751G Control relay

-

triconex 3382 Pulse Input Module, Enhanced

-

triconex 3451 Solid-State Relay Output Module

-

triconex Digital Output Module, Supervised 3411

-

triconex Digital Output Module 3401

-

triconex Digital Input Module, High Resolution 3311

-

triconex Digital Input Module 3301

-

triconex 3482 High-Current Analog Output Module

-

triconex Model 3481 Analog Output Module

-

Triconex 9793-610F Analog Input/Digital Input Termination Panels Kit, Hazardous Location

-

Triconex 9573-610F Digital Input Termination Panel Kit, Hazardous Location

-

Triconex 2483 Analog Output Baseplate Kit, HART 2483A

-

Triconex 2481 Analog Output Baseplate Kit

-

Triconex 2480A-F Analog Output Baseplate Kit, Hazardous Location

-

Triconex 2451 Solid-State Relay Output Baseplate Kit

-

Triconex 2402-F Digital Output Baseplate Kit, High Voltage 2402A-F

-

Triconex 2401 Digital Output Baseplate Kit 2401H 2401L

-

Triconex 2381 Pulse Input Baseplate Kit 2381A

-

Triconex 2361 Analog Input/Digital Input Baseplate Kit

-

Triconex 2354 Analog Input Baseplate Kit, HART 2354A

-

Triconex 2352A-F Analog Input Baseplate Kit, Hazardous Location

-

Triconex 2352 Analog Input Baseplate Kit for TC, RTD, and 4-20mA (requires 2 of part number 9764-510F)

-

Triconex 2351 Analog Input Baseplate Kit

-

Triconex 2342 Analog Input/Digital Input Baseplate Kit External Termination 2342A-F

-

Triconex 2302-F Digital Input Baseplate Kit, High Voltage 2302A-F

-

Triconex 2301 Digital Input Baseplate Kit

-

Triconex 2292 I/O Bus Termination Kit, MP Baseplate

-

Triconex 2291 I/O Bus Termination Kit, I/O Baseplate

-

Triconex 2281 I/O Bus Extender Module Kit

-

Triconex 2211 Communications Integration Module Baseplate Kit

-

Triconex 2201 Communications Module Baseplate Kit

-

Triconex 2101 Main Processor Baseplate Kit

-

Triconex 5483 Analog Output TriPak, HART 5483A

-

Triconex 5382A Pulse Input TriPak, Enhanced, Hazardous Location

-

Triconex 5382-1 Pulse Input TriPak, Enhanced

-

Triconex 5451 Solid-State Relay Output TriPak

-

Triconex 5402-F Digital Output TriPak, High Voltage

-

Triconex 5411H Digital Output TriPak, Supervised, High Current

-

Triconex Digital Output TriPak, Low Current 5401L

-

Triconex Digital Output TriPak 5401

-

Triconex Digital Input TriPak, High Voltage 5302-F

-

Triconex Digital Input TriPak, High Resolution, High Voltage 5312-F

-

Triconex Digital Input TriPak, High Resolution 5311

-

Triconex Digital Input TriPak 5301

-

SAR 12 029.379519 GE Ring antenna CV(Restricted products)

-

Triconex Analog Output Tripak High-Current 5482-1

-

Triconex Analog Output TriPak 5481-1

-

Triconex Analog Input TriPak HART Hazardous Location 5354A 5354AS2

-

Triconex Analog Input TriPak HART 5354 5354S2

-

Triconex Analog Input Tripak RTD/TC/4-20 mA 5352 5352S2

-

Triconex Analog Input/Digital Input TriPak 5361 5361S2

-

Triconex Analog Input TriPak 5351 5351S2

-

Triconex Communication Module TriPak 5201 5201S2

-

Triconex Communications Integration Module TriPak 5211 5211S2

-

triconex Main Processor TriPak 5101 5101S2

-

TRICONEX 2211 Discrete input/output module

-

CIM3211 Triconex Tricon Communication Model

-

triconex Communication Module cm3201

-

MICRO INNOVATIONDISPLAY INTERFACE PANLE MC2-442-57CQB-1-2G

-

ABB NextMove ESB-2 motion controller

-

IS200SSCHAH2A GE COMMUNICATION TERMINATION TERMIINAL

-

GE IS200WREAH1A PROTE INTERFACE BOARD, EMERG

-

GE IS420UCSCH1B Processing Module UCSC QUAD CORE 1.2GHZ 4GB CONTROLLER

-

UniOP eTOP33C HMI touch unit Product Overview

-

ABB DRIVEMONITOR VERSION 4000 DRIVE RBOX316-ABB-00

-

MOTOROLA MVME5110 VMEbus Single Board Computer Specification

-

GE Grid Solutions Feeder Protection System 350-E-P5-S5-H-E-E-N-N-4E-D-N

-

ABB AFS670 19" Ruggedized Switch AFS670-EREEDDDSSEEEEEEEPZYX05.1.0

-

ABB P8461 digital output 24/48V DC UNIT

-

ABB SCC-K Converter-Without Any Accessories Included Advance

-

UNIOP EPALM10-DA71 state-of-the-art handheld HMI

-

ALSTOM BINARY INPUT BOARD 23BI61R1LF 1KWU300080 R1001E

-

ALSTOM LOCAL CONTROL PANEL DRWLM028-Q69-LCP-02S WITCH WIT AC120A

-

MOOG D136-002-005 MSC I and MSC II Motion Controllers D136002005

-

Honeywell CC-PAIX02 I/O Module Sizes High-level AI w/o HART - Differential

-

KEBA PI 050/A DC-link power supply PI050/B keplast i1000

-

WOODWARD 9907-1213 TM-25LP Single Coil Extend

-

GE GDS1168-FF-HCS-NF ALSTOM Power unit

-

GE control board GDS1168-SFP-HCS-NF (PIBE) PLX111909955 ALSTOM Power unit

-

GE IS400JPDMG1A PDM General Electric 28VDC

-

TMEIC (Toshiba-Mitsubishi)ARND-3119A Distributed control panel

-

ABB SCC-C Sample gas cooler 23070-0-103101100000

-

ABB 3BHE014557R0006 UNITROL1000-15 Controller drive unit

-

DS200TBQGG1ABB | GE Common Analog I/O Board

-

ABB 3BHE051589R0102 INU INTERFACE BOARD

-

GE Multilin C60-V03-HLH-F8L-H6DM6D-P6C-U6C-W6C Comprehensive Protection for Generators unit

-

GE Multilin G60G01HKHF8FH67M8FP6DU6D Comprehensive Protection for Generators unit

-

ABB SCC-F Sample gas cooler SCCF 23212-0-121210000000

-

GE Multilin F650BFBF1G0HIP feeder protection relay F650-B-F-B-F-1-G-0-HI-P

-

ABB Inspirational system HIEE300661R0001 UPC090AE01 ARCnet Coupler Card

-

Hirschmann MM20-Z6Z6Z6Z6SBHH Ethernet media module

-

Hirschmann MM20-Z6Z6Z6Z6SAHH Ethernet media module

-

ABB Detector 13CO2 10% URAS 14 analyzer AO2040 769137C

-

GE/CONVERTEAM ADVANCED MICRO CONTROLLER P111-6053

All new products and surplus products of the industrial intelligence industry, as well as the discontinued products of the original manufacturers. We are not an authorized distributor or representative of any of the above manufacturers (except for brand authorization). The trademarks, brand names and brands appearing in this agreement are the property of their respective manufacturers.

COPYRIGHT© 2003-2025 Copyrighted

Phone(WeChat/Whatsapp)

+086-181 4410 0983

No 1134 Jimei North Road,

Hong Kong Office:

Guan Tang District, Hong Kong,